Sprockets Market Value Share, Supply Demand, share and Value Chain 2018 to 2027

ROCKVILLE, United States, 2021-Mar-08 — /EPR Network/ —

Sprockets, used to transmit rotary motion between two shafts or to impart linear motion to a track, find application in bicycles, motorcycles, tracked vehicles and other machinery. Sprockets are also increasingly used in machine tools or material handling equipment for mining and construction industries due to their significant attributes including superior durability in extreme conditions, high-load capacity, low, vibrations, and providing noiseless operations in industries. These factors are likely to favor major growth of the global sprockets market. Sprockets are generally made from non-corrosive and robust materials which ensure a long product life even in harsh industrial environment which in turn increase their demand.

This Press Release will help you to understand the market Statistics of the European Region.

Click HERE To get a SAMPLE PDF (Including Full TOC, Table & Figures) at https://www.factmr.com/connectus/sample?flag=S&rep_id=707

Global Sprockets Market to Grow Significantly in Asia Pacific

Asia Pacific is expected to contribute major revenue growth of the sprockets market owing to rapid industrial growth coupled with increasing motorcycle production. Rising utilization of sprockets in various industries including oil & gas, food & beverages, and mining industries is expected to drive the market growth in the Asia Pacific region. Presence of large number of population with varying requirements and increasing demand for petrochemicals and energy in the region will possibly fuel the growth of sprockets market. Further, increasing servicing and replacement activities for material handling equipment is likely to propel the growth of sprockets market.

Promising Future for Motorcycles to Fuel Growth of Sprockets Market

Sprockets, toothed wheels designed for engaging with components such as chains and belts to pull over the wheel, typically seek adoption in motorcycles. Size of the sprockets are reduced or increased to comply with different gearing of motorcycles, enabling drivers to make their movements efficient and powerful. Sprockets also seek adoption in various other types of motorized vehicles.

An influx of household in cities of industrializing countries coupled with elevating GHDI of consumers in these countries has been reflecting on demand for motorcycles over the past few years. The global motorcycle industry witnessed a slack owing to intensified import competition in the recent past, which led several manufacturers to relocate their production plants to emerging markets, where demand has been rising significantly. However, remarkable opportunity exists for growth of the global motorcycle industry in the upcoming years, wherein overall supply chain participants in the industry are emphasizing on integration and incorporation of business intelligence and advanced analytics.

Need more information about Report Methodology? Click here- https://www.factmr.com/connectus/sample?flag=RM&rep_id=707

Industry participants are taking efforts to counteract the past slack by increasing efficacy of their production facilities, meanwhile tapping the demographic segments other than Baby Boomers such as young, female and minority population, with attractive marketing strategies such as celebrity endorsements. Such efforts will reflect on the growing demand for motorcycles, thereby fuelling growth of the sprockets market.

Robust Expansion of Material Handling Industry to Influence Demand for Sprockets

Sprockets form an integral component of various material handling equipment that seek adoption across most industrial sectors including construction, mining, oil & gas, and machine tools. Superior durability even in extreme operating conditions, noise-free operations, high-load capacity, and low vibration are key attributes of sprockets that make their use in material handling equipment lucrative. Future of material handling is foreseen to be smart, with growing interconnection between technologies and equipment, also known as “Industrial Internet of Things (IIoT)”.

Smart manufacturing enterprises are focusing on maximizing their efficiency and safety via intuitive collaboration and networking with their customers. The overall manufacturing floor – from picking & sorting systems to conveying systems – are witnessing evolution for accommodating more flexible business requirements and predictive planning. Abreast these evolvements, demand for various innate material handling components such as sprockets is likely to gain an uptick in the near future.

To receive an extensive list of important regions, ask for TOC here- https://www.factmr.com/connectus/sample?flag=T&rep_id=707

Proliferation of Industrial Robotics to Create High Demand for Sprockets

Industrial robotics imparts myriad benefits in terms of operational precision, quality, and productivity, and its deployment in industrial sectors entails the need for high-degree precision control. Advancements in robotic vision has significantly fuelled the efficiency of industrial processes since the recent past. Growing popularity of artificial intelligence (AI), along with evolution of technologies incorporated in robotics have led toward the development of advanced robots with improved vision capabilities.

This has created high demand for components such as gears, drives and sprockets for ensuring better precision control and flexibility of robots during their deployment. With components such as sprockets assisting robots to control directional and rotational motion, and cascading effect of demand for customized robots is likely to prompt vendors of sprockets to improve their design capabilities and develop new technology.

For example, Pitsco, Inc. has recently introduced its TETRIX®MAX Sprockets, which are manufactured from heavy-duty aluminum, designed for competitive and tough robots, and offer high performance even in heavy load operations. Product variants of the lightweight yet sturdy TETRIX®MAX Sprockets include 16-tooth, 24-tooth, and 32-tooth sprockets with 3-D animation.

Key Developments from Manufacturers

- RENOLD, a prominent manufacturer of material handling components, has recently developed a new array of high-performance sprockets. These sprockets have been made available by the company in pitch sizes 06B-16B simplex in the pilot bore configuration. RENOLD’s new high-performance sprockets are manufactured by using C45-grade carbon steel, and comply with ISO 606 standard. Teeth of these sprockets are induction hardened to tight tolerance in 40-50 HRC range.

- Tsubaki, leading manufacturers of various industry-specific transmission equipment & component, has unveiled its new range of sprockets made from high-quality, heat-treated steel. These sprockets are claimed to perform well in all kinds of challenging and heavy-duty applications. Resistant to wear and shock loads, Tsubaki’s new sprockets require minimal maintenance.

This analytical research study imparts an all-inclusive assessment on the market, while propounding historical intelligence, actionable insights, and industry-validated & statistically-upheld market forecast. Verified and suitable set of assumptions and methodology has been leveraged for developing this comprehensive study. Information and analysis on key market segments incorporated in the report has been delivered in weighted chapters. A thorough analysis has been offered by the report on

- Market Dynamics

- Market Size

- Market Segments

- Demand & Supply Trends

- Current Issues and Challenges

- Companies and Competitor Landscape

- Value Chain

- Technology

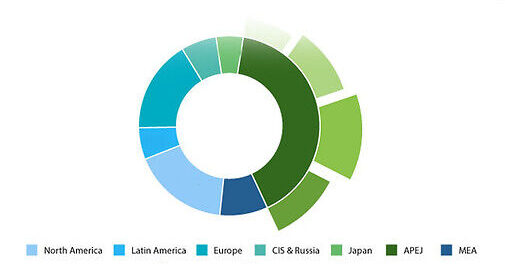

Regional Segments Analyzed Include

- North America (U.S., Canada)

- Latin America (Mexico. Brazil)

- Western Europe (Germany, Italy, France, U.K, Spain)

- Eastern Europe (Poland, Russia)

- Asia Pacific (China, India, ASEAN, Australia & New Zealand)

- Japan

- Middle East and Africa (GCC, S. Africa, N. Africa)

About Us:

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Our sales offices in United States and Dublin, Ireland. Headquarter based in Dubai, UAE. Reach out to us with your goals, and we’ll be an able research partner.

Contact:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

Jumeirah Lakes Towers,

Dubai, United Arab Emirates